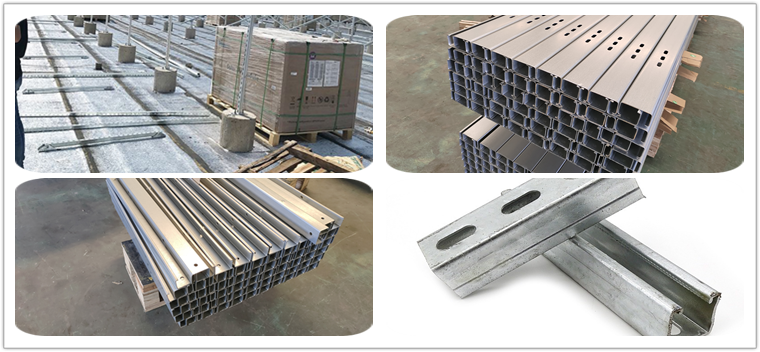

Zn-Al-Mg Coated Steel Ground Mounting Bracket Strucuture

Features

Zn -Al - Mg coated steel ground mounting system is made of zinc aluminum magnesium coated steel which is a new type of high corrosion resistant coating plate with long service life and stable structure, and can be used in various extreme environments.

Advantage

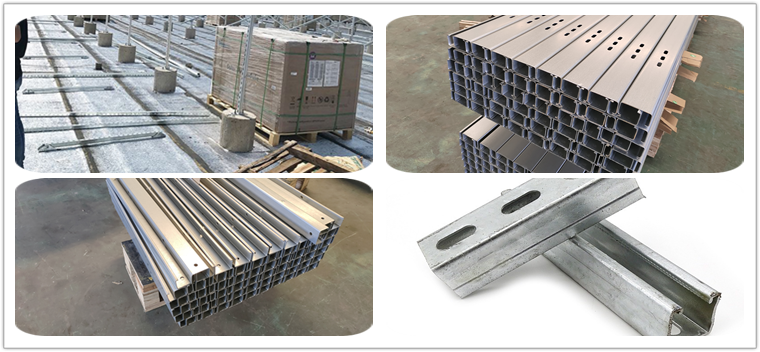

1. Material features with high strength, superior corrosion resistance, self-repair, long lasting and easy processing

2 . No need for post - coated or smeared , reducing the costs of rust -proof or paint repair on site

3 . Conventional specification can be mass -produced to maximum control of production cycle

Technical Parameter

|

Parameter

|

Description

|

Material

|

Q355

|

Design Standard

|

JIS C8955 -2011.AS/NZS 1170.0,IEC62817,etc.

|

Foundation Type

|

Driven Pile, Ground Screw or Concrete

|

Galvanized Thickness

|

70um -100um, Per Local Codes

|

Wind Load

|

≤60m/s, Per Local Codes

|

Snow Load

|

≤16KN/M,Per Local Codes

|

Module Type

|

Frame or frameless

|

Panel Layout

|

Portrait or Landscape

|

Service Life

|

≥30 years

|

Warranty

|

20 years

|

Product Advantage

By the optimized mechanical calculation, the structure can withstand tropical cyclone speed up to 32.7m/s. Production process is run by ISO9001 quality management system to ensure product quality. Design in accordance with JIS standard (Japan), AS/NZS 1170.2 (AU/NZ), CE, TUV, SGS Quality Testing and other international standards.

-

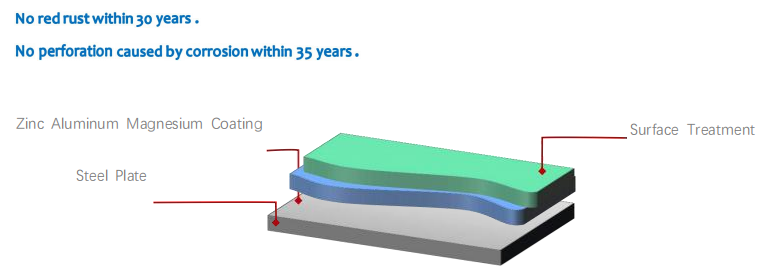

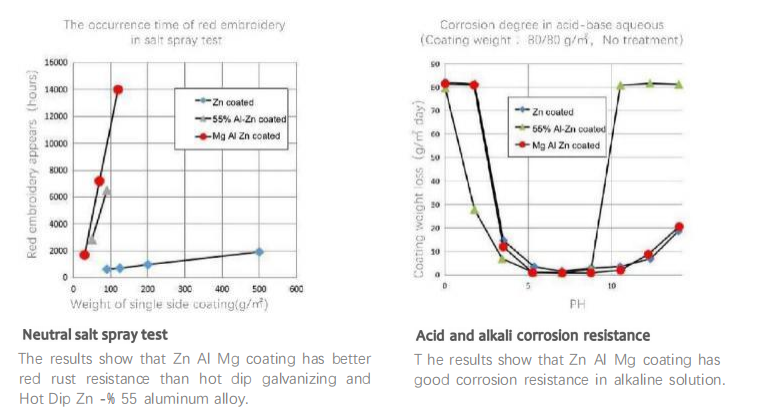

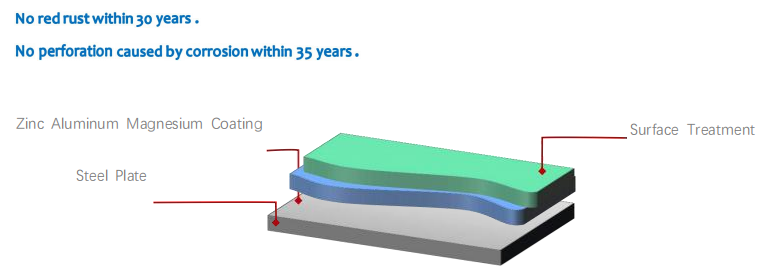

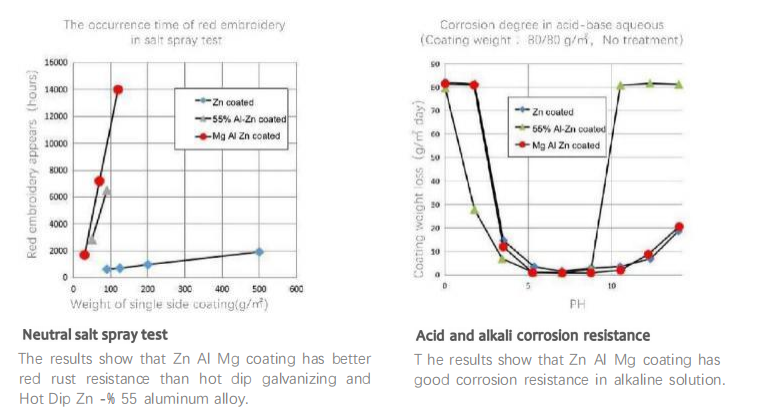

Super corrosion resistance. Al, Mg, Si and other alloy elements are added to the coating of magnesium aluminum zinc plating steel plate, which greatly improves the corrosion inhibition effect of the coating. Compared to ordinary galvanized products , the coating has less adhesion , but it can achieve better. corrosion resistance, which is 10 -20 times of that of hot -dip galvanized steel plate.

-

Long service life. Due to the super corrosion resistance of 10 -20 times that of ordinary hot -dip galvanized sheet and the corrosion resistance self healing effect of cutting section, the service life of the structure made of hot -dip Mg-Al-Zn alloy coated sheet will be very long, generally, it can reach more than 30 years.

-

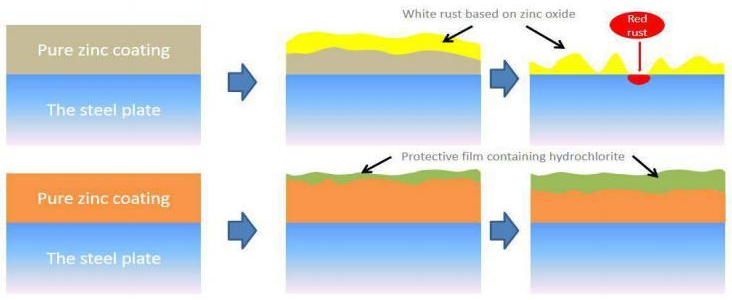

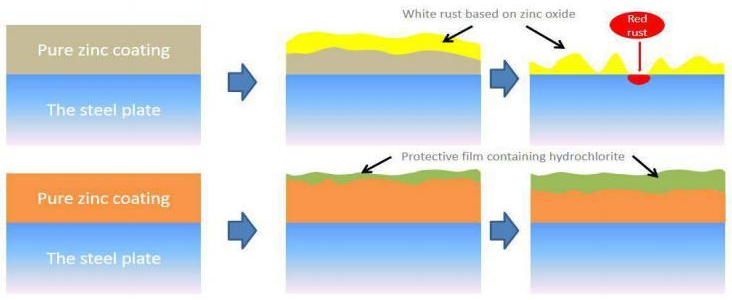

After self-healing The components of the coating around the cutting surface are continuously dissolved to form a dense protective film mainly composed of zinc hydroxide, alkaline zinc chloride and magnesium hydroxide. This protective film has low conductivity and has inhibition effect on the corrosion of the cutting surface.

-

It is easy to process The coating of hot -dip mg Al, Zn plating steel plate is more dense than that of galvanized steel plate, so it is not easy to peel off during stamping processing. It has excellent processing properties such as tensile, stamping, bending and welding under severe conditions, and has excellent damage resistance due to its high hardness.

-

Low cost lower cost (generally 30% cheaper than aluminium profile).

Coated Zn-Al-Mg Advantage

Due to the coarseness of the surface to be protected, water molecules and air are easy to penetrate into the galvanized steel sheet, so red rust still occurs after a period of time. However, due to its dense protective film, the coating of magnesium aluminum zinc can prevent water molecules and air from penetrating into the steel sheet , so as to avoid the occurrence of red rust and achieve a higher corrosion.

+86 15959271231

+86 15959271231 xmjiazhijing@126.com

xmjiazhijing@126.com

+86 15959271231

+86 15959271231 xmjiazhijing@126.com

xmjiazhijing@126.com