+86 15959271231

+86 15959271231 xmjiazhijing@126.com

xmjiazhijing@126.com

+86 15959271231

+86 15959271231 xmjiazhijing@126.com

xmjiazhijing@126.com

Photovoltaic brackets, also called solar photovoltaic brackets, refer to special functional brackets used to install, support, and fix photovoltaic modules in photovoltaic power generation systems. By combining the topography, climate and solar resource conditions of the project site, the designer uses photovoltaic brackets to fix the photovoltaic modules in a certain orientation, arrangement and spacing, so that the entire photovoltaic power station can obtain maximum power output.

The upstream of the photovoltaic bracket industry is mainly metal materials such as steel, and other raw materials include galvanizing, machinery and electronic components. The midstream is the manufacturing of photovoltaic brackets. Since photovoltaic brackets are non-standardized production products, there are usually three modes in the midstream: R&D design + manufacturing; R&D design + outsourced production; and production OEM. The downstream of the industry mainly includes the development and construction of photovoltaic power stations, as well as subsequent operation and maintenance needs.

In terms of materials, there are three main types of photovoltaic brackets on the market: hot-dip galvanized, galvanized aluminum-magnesium, and weather-resistant steel brackets.

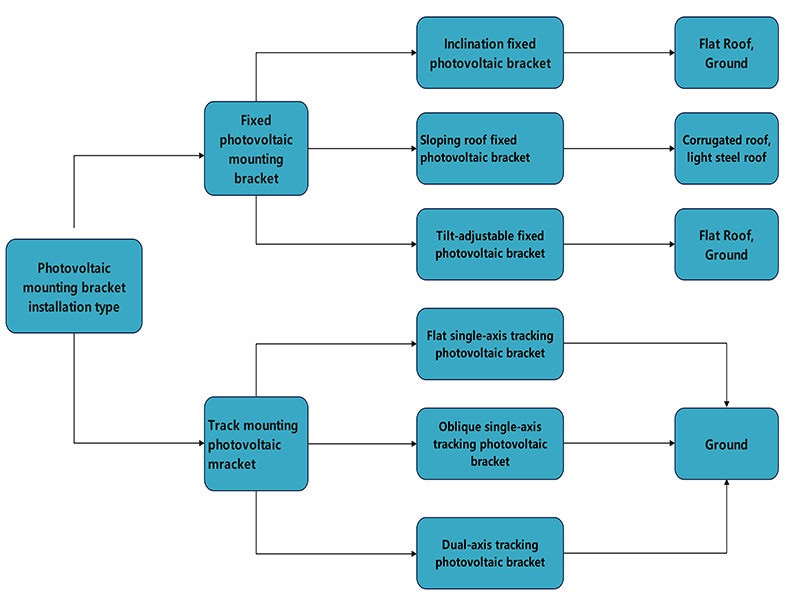

From the type point of view, photovoltaic brackets can be divided into three types: fixed, tilt-adjustable and automatic tracking. The connection methods are generally welding and assembly. Fixed brackets are divided into roof brackets, ground brackets and water surface brackets; automatic tracking brackets are divided into single-axis tracking brackets and dual-axis tracking brackets.

Common photovoltaic brackets are composed of rear columns, front columns, cross beams, inclined beams, connectors, etc., and are connected by bolts, plastic wing nuts, etc. to form a structure. The battery components are connected with the bracket beams using pressure blocks to form a unit as a whole.

Photovoltaic bracket cost structure

Looking at the cost structure of photovoltaic tracking brackets, steel accounts for the highest proportion, exceeding 60%. In addition to steel, the costs of rotary reduction devices, electric control boxes, and galvanizing are also its main cost components, accounting for 12.1%, 9.9%, and 7.4% respectively. Manufacturing expenses and labor costs account for a small proportion, 3.2% and 2.1% respectively.

Photovoltaic bracket market size

As the "skeleton" of the photovoltaic power station, the performance of the photovoltaic bracket directly affects the power generation efficiency and investment income of the photovoltaic power station. It is one of the main equipment of all ground photovoltaic power stations. According to data from relevant research institutions, China's photovoltaic bracket market size will be 19 billion yuan in 2022, a year-on-year increase of 8.6%. As China continues to increase its installed photovoltaic capacity, it is expected that the market size of photovoltaic brackets will continue to increase steadily in the future. Industry analysts predict that China’s photovoltaic bracket market will reach 21 billion yuan in 2023 and increase to 25.3 billion yuan in 2024.

Photovoltaic stent penetration rate

As the market's acceptance of photovoltaic stents increases, the penetration rate of photovoltaic stents in China continues to increase. Data shows that the penetration rate of photovoltaic stents will gradually increase from 16% in 2019 to 23% in 2022. Industry analysts predict that driven by photovoltaic market demand, the market penetration rate of China's photovoltaic stents is expected to further increase, reaching 25.3% by the end of 2023 and 29.5% in 2024.

Industrial prospects

- 1. The increase in penetration rate drives the development of the industry.

As the reliability of tracking brackets improves, the cost decreases, and the trend of photovoltaic grid parity forces power plant investors to pay more attention to power generation efficiency and other factors, the demand for tracking brackets is rapidly increasing in emerging photovoltaic markets, especially in Asia Pacific, the Middle East, Australia and Africa. Affected by the increasing penetration rate, the industry has good development prospects.

- 2. Policies are beneficial to the development of the industry.

In recent years, the photovoltaic bracket industry in various countries has received great attention from governments at all levels and key support from national industrial policies. Many countries have successively introduced a number of policies to encourage the development and innovation of the photovoltaic industry.

- 3. The construction of centralized ground power stations is accelerating, and the market share of brackets will steadily increase.

With the decline in polysilicon prices and component prices, the overall price reduction trend in the photovoltaic industry chain is significant. The price drop will drive the rapid growth of global ground-based centralized power stations, and the downstream photovoltaic links will continue to benefit. Under the trend of expansion of supply chain capacity, falling component prices and the fact that the first batch of large wind power and photovoltaic bases are about to be connected to the grid, China's centralized photovoltaic installed capacity will increase significantly in 2023, and the construction of large centralized ground power stations will promote the use of tracking support systems . In the future, as its cost decreases and reliability is improved, the market share of tracking brackets will steadily increase.