+86 15959271231

+86 15959271231 xmjiazhijing@126.com

xmjiazhijing@126.com

+86 15959271231

+86 15959271231 xmjiazhijing@126.com

xmjiazhijing@126.com

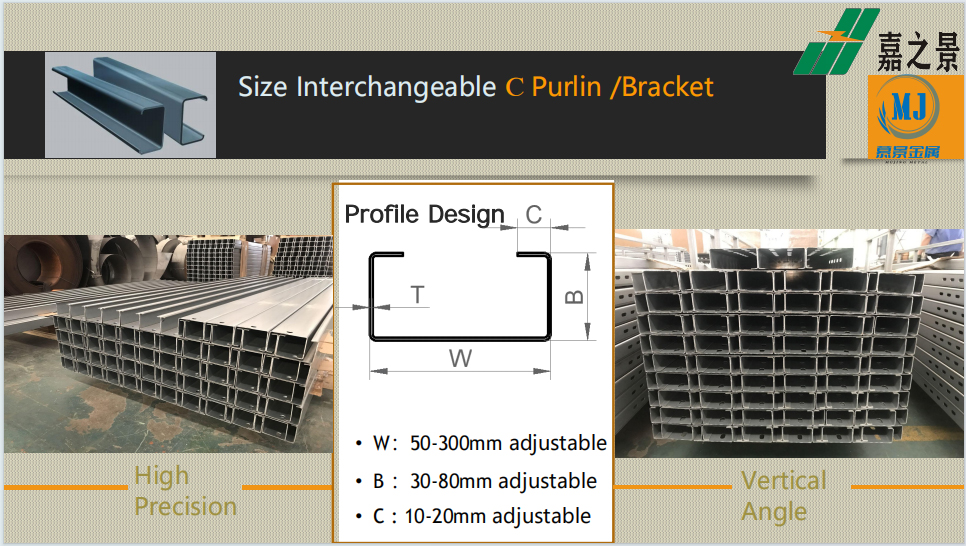

Size: C60-300

Height: 30-80mm

Hot Diameter: customizable

Lip: 5-15m

Material Thickness: 1.5-3mm

Suitable Material: Galvanized coated coil, Zn-Al-Mg coil

Surface treatment: Zinc coated at 60-80u

PV bracket support beams play a key role in pv power generation systems. They provide stable and efficient support for pv modules and adapt to various harsh environments. This helps achieve sustainable clean energy supply and reduce dependence on traditional fossil energy sources.

Supporting pv modules: Support beams are responsible for carrying and fixing pv modules so that pv modules can be installed smoothly on the ground or on the roof of a building, thereby ensuring the stable operation of the pv power generation system.

Adjust module inclination angle: The inclination angle adjustment device on the support beam allows users to adjust the inclination angle of pv modules according to different seasons and geographical locations to obtain the best solar radiation effect. This helps improve the efficiency of pv power generation systems.

Wind and compression resistance: Support beams need to have sufficient strength and stability to resist the impact of wind and other natural factors on photovoltaic modules. In areas with strong winds, the thickness of the support beams will be increased accordingly to enhance wind resistance.

Anti-corrosion and weather resistance: PV support beams are usually made of anti-corrosion materials, such as hot-dip galvanizing, galvanized aluminum-magnesium and weather-resistant steel, to resist environmental corrosion and wear and extend service life.

Adapt to different environments: PV support beams need to adapt to various harsh environments, such as high temperature, low temperature, humidity, ultraviolet radiation, etc., to ensure the stable operation of the pv power generation system.

Easy to install and maintain: The design of the pv bracket support beam should be easy to install, disassemble and maintain to reduce installation and operation and maintenance costs.

Effetive Width

60-300mm

Height

40-80mm

Suitable Material

Q235, Q355, Zn-Al-Mg coated steel coil

Avaliable Material Thickness

1.5-3mm

Surface Treatment

Zinc coated at 60-80u, according to end user's requirements